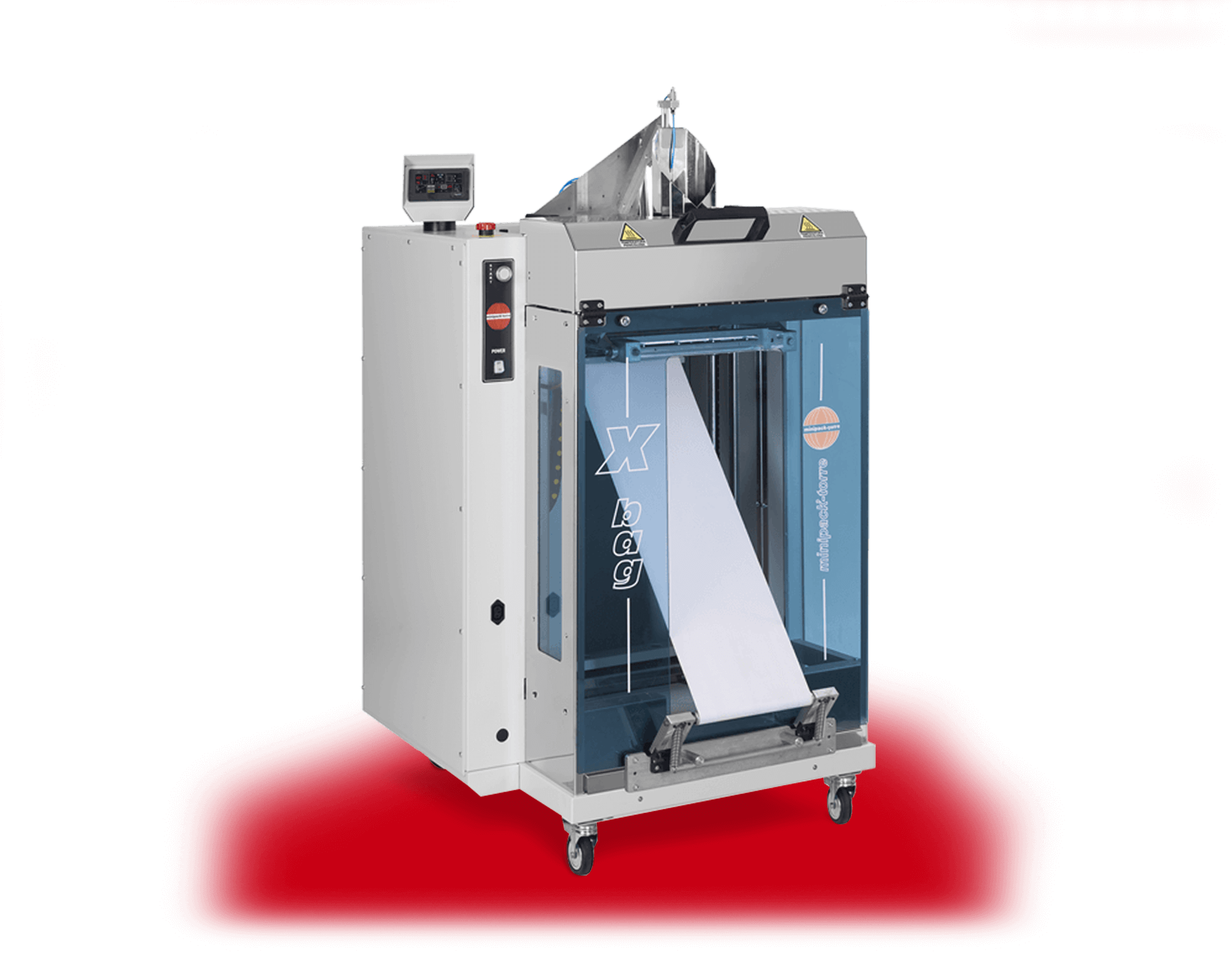

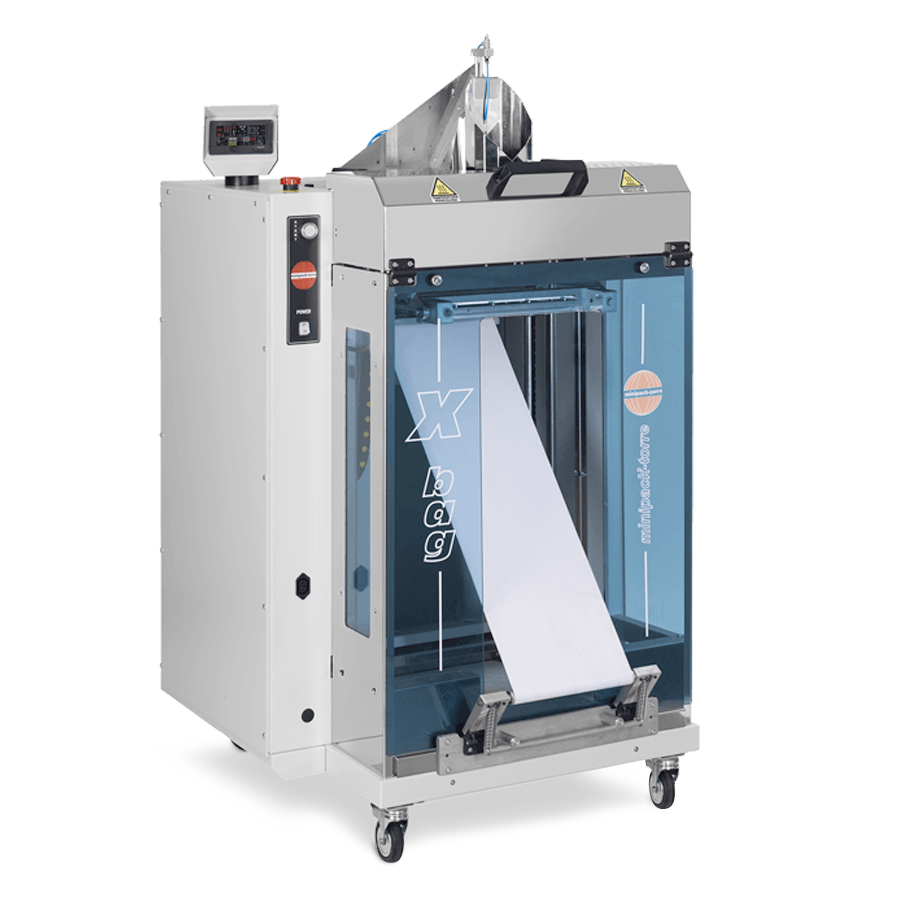

X Bag

The X-BAG evo is the ideal solution for those who need to bag small quantities of material quickly (fresh food, small parts, spare parts, instruction manuals, small dimension industrial components, etc.), in airtight packages, with different formats and different types of film.

Easy to use. Easy to maintain. Easy to place.

The X-BAG evo simplifies packaging operations: for this reason it represents a valid alternative to manual packaging, which is more costly in terms of time, but also to automatic packaging with larger and more complex machines which is often inadequate for real packaging needs, and involves higher operating and maintenance costs. Practical and handy, the X-BAG evo works continuously or in impulse mode. Thanks to its small size, it can find a place in any size of room, even in restricted areas.

All the virtues of the X-Bag

Compact

Only 140 cm high on an 80x85 cm base so that it can be located easily in any kind of space, even in small production areas.

Simple

Basic in everything from structure to operation, working continuously or in impulse mode, so as to reduce machine preparation, loading, programming and maintenance times.

Innovative

Basic in everything from structure to operation, working continuously or in impulse mode, so as to reduce machine preparation, loading, programming and maintenance times.

Pratical

Quick collar replacement for format switching to reduce machine downtime and increase productivity.

Technology

New Schneider Electric colour touch screen with simple, intuitive graphics for even easier management of all machine parameters.

Economical

The initial investment pays for itself with reduced processing times and hence reduced cost of bagging labour, as well as with savings on packaging material.

Multisector

The X-BAG evo can be used in various sectors and environments; bakeries, supermarkets, fruit and vegetable markets, health and hospital facilities, hardware stores, logistics centres, spare parts warehouses, manufacturing facilities.

Technical characteristics

- Power supply: 220/240 V

- Max installed power: 0.5 kW

- Pneumatic supply: 40 l/m bar up to 6 bar

- Hourly production: 0-1000 pcs/h

- Max reel dimensions (diameter): 250 mm

- Max reel dimensions (width): 360/410/520 mm

- Film thickness: 15/50 microns

- Length of package: 50/330 mm

- Width of package: 170/185/235 mm (depending on collar)

- Machinable film: types - Polyethylene, polyolefin, macro-perforated, laminated, biodegradable film, carotene plastic, printed film

- Horizontal sealing: double strip and cutting line type

- Machine dimensions: 800x850x1500 mm

- Machine weight (Net/Gross): 130/170 Kg

Find out about our automatic packaging solutions

Shrink tunnel

The shrink tunnels have been built with significant technical and aesthetic updates, in order to...

Chamber machines

We have never abandoned our pioneering spirit. It was in fact the invention of the first chamber...

Automatic

The new model of automatic shrink wrap machine is the result of constant attention to market needs,...

Taping machines

We have a wide range of fixed or fully robotised pallet wrappers. Extremely fast, sturdy machines...

Check Weigher

This is used to check whether the weight of an individual package conforms to the preset weight or...

X Bag

X-BAG evo is the ideal solution for those who need to pack small quantities of material quickly...

Doy-Pack packaging machines

The Doy Pack packaging machine is the latest generation of horizontal equipment.

Strada del Cascinotto 230 - 10156 - Turin

Turin+39.011.99.10.455

Mon - Fri 8.30 - 18.30info@dmpackagingroup.com

Technical support

Are you looking for more performing industrial automatic systems?

ask for the support of HBTS, the dedicated DM Packaging Group brand