Pallet wrappers

To stabilise and protect pallets with stretch film, saving time and material, Packaging

Easy Tab 2000

The Easy TAB 2000 W model is a semi-automatic machine for wrapping palletised loads with stretch film: with the possibility of inserting a forklift, adjustment of film tensioning by mechanical brake, gradual start of the table by inverter, manual or automatic work cycle, possibility of adjusting the number of wraps on the bottom and top of the pallet.

Technical characteristics

- Machine structure in painted sheet steel

- Hinged column at the base for quick, easy installation

- Transmission of reel-holder carriage by chain

- Table diameter 1500 mm shaped to take pallet truck

- Working height 2400 mm

- Ambient conditions humidity: ≤ 90\%

- Working temperature: from + 0°C to + 40°C

- Mechanical clutch

- Possibility of lifting the machine from both front and rear with the forklift

- Provision for pneumatic press • • Inverter for progressive table starting and indexed stopping

- Digital adjustment of wraps at the base of the pallet

- Digital adjustment of wraps at the top of the pallet

- Rotation speed adjustable from 0 to 10 rpm.

- Carriage up and down speed

- Photocell reading delay

- Buttons for man/aut machine management

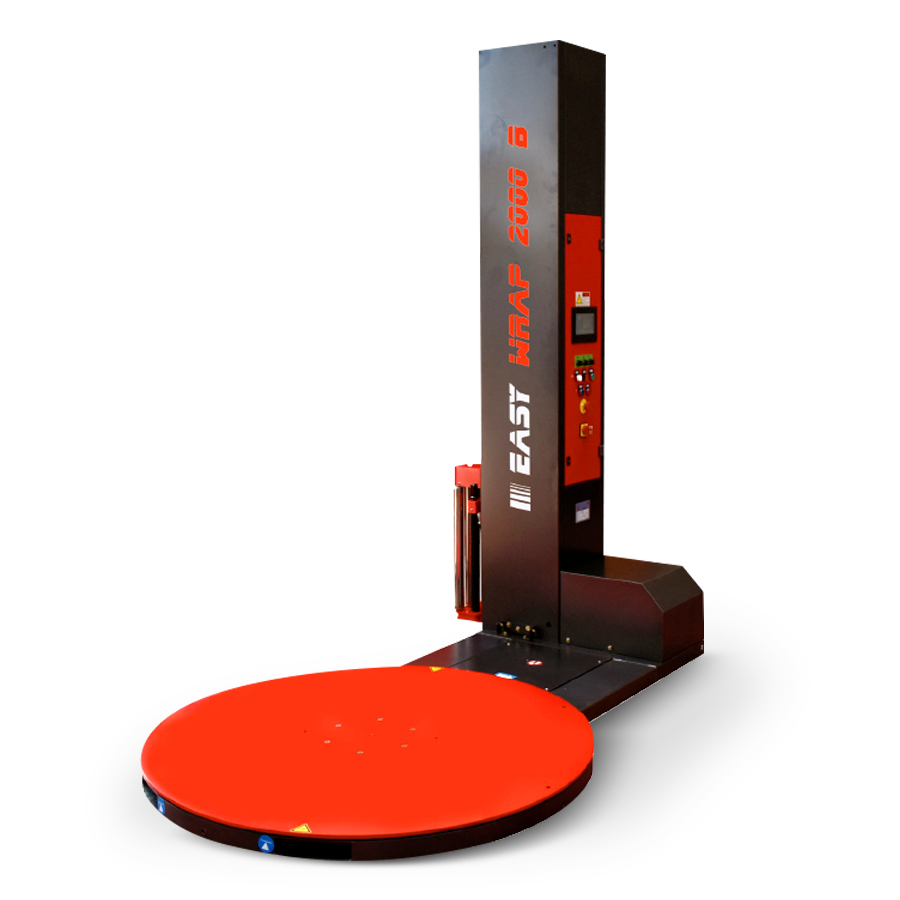

Easy Wrap 2000

The Easy Wrap 2000 A is a semi-automatic machine for wrapping palletised loads with stretch film: with the possibility of adjusting film tensioning by mechanical brake, gradual start of the table by inverter, manual or automatic work cycle, possibility of adjusting the number of wraps on the lower and upper part of the pallet.

Technical characteristics

- Machine structure in painted sheet steel

- Hinged column at the base for quick, easy installation

- Transmission of reel-holder carriage by chain

- Table diameter 1500 mm

- Working height 2400 mm

- Ambient conditions humidity: ≤ 90\%

- Working temperature: from + 0°C to + 40°C

- Possibility of lifting the machine from both front and rear with the forklift

- Provision for pneumatic press

- Inverter for progressive table starting and indexed stopping

- Digital adjustment of wraps at the base of the pallet

- Digital adjustment of wraps at the top of the pallet

- Rotation speed adjustable from 0 to 10 rpm.

- Carriage up and down speed

- Photocell reading delay

- Buttons for man/aut machine management

- Up and down cycle

- Up only cycle

- Feeder cycle

- Max.film reel height : 500 mm

- Max. reel diameter: 280 mm

- Max pallet dimensions : 800 x 1200 x 2200 mm

- Table capacity : 1500 Kg

- Machine weight : 650 Kg

- Installed power : 1 kW

- Machine dimensions : 2715 x 1515 x 2600 mm

- Machines manufactured according to CE standards

Robot wrap 600A

The Robot Wrap 600A is a self-propelled wrapping robot for palletised loads of any shape, size and weight with stretch film. It is equipped with a digital touch screen control panel that means simple, functional management of the programs and the setting of the wrapping parameters.Film tensioning can be adjusted by means of a mechanical brake.

Technical characteristics

- Hinged column at the base for quick, easy installation

- Transmission of reel-holder carriage by chain

- Working height 2400 mm

- Ambient conditions humidity: ≤ 90\%

- Working temperature: from + 0°C to + 40°C

- 1300 mm additional to product radius necessary for function

- Mushroom head emergency button for CE standards

- Safety bumper for machine stop

- Max rotation speed 90 m/min

- Handlebar for easy handling of motorised robot

- Height-adjustable side feeler wheel

- Liftable from the side

- Colour touch screen control panel

- Machine controlled by plc SIEMENS S7/1200

- Autonomy up to 200 pallets without recharging (W 800x L1200X1600mm)

- Emergency wheel in case of low battery

- Digital adjustment of wraps at the base of the pallet

- Digital adjustment of wraps at the top of the pallet

- Rotation speed adjustment

- Carriage up speed adjustment

- Adjustment and control of film tension

- Carriage down speed adjustment

- Photocell reading delay

- Buttons for man/aut machine management

Find out about our automatic packaging solutions

Shrink tunnel

The shrink tunnels have been built with significant technical and aesthetic updates, in order to...

Chamber machines

We have never abandoned our pioneering spirit. It was in fact the invention of the first chamber...

Automatic

The new model of automatic shrink wrap machine is the result of constant attention to market needs,...

Taping machines

We have a wide range of fixed or fully robotised pallet wrappers. Extremely fast, sturdy machines...

Check Weigher

This is used to check whether the weight of an individual package conforms to the preset weight or...

X Bag

X-BAG evo is the ideal solution for those who need to pack small quantities of material quickly...

Doy-Pack packaging machines

The Doy Pack packaging machine is the latest generation of horizontal equipment.

Strada del Cascinotto 230 - 10156 - Turin

Turin+39.011.99.10.455

Mon - Fri 8.30 - 18.30info@dmpackagingroup.com

Technical support

Are you looking for more performing industrial automatic systems?

ask for the support of HBTS, the dedicated DM Packaging Group brand