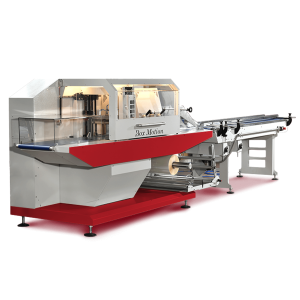

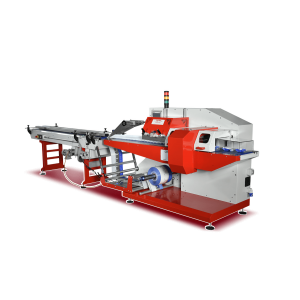

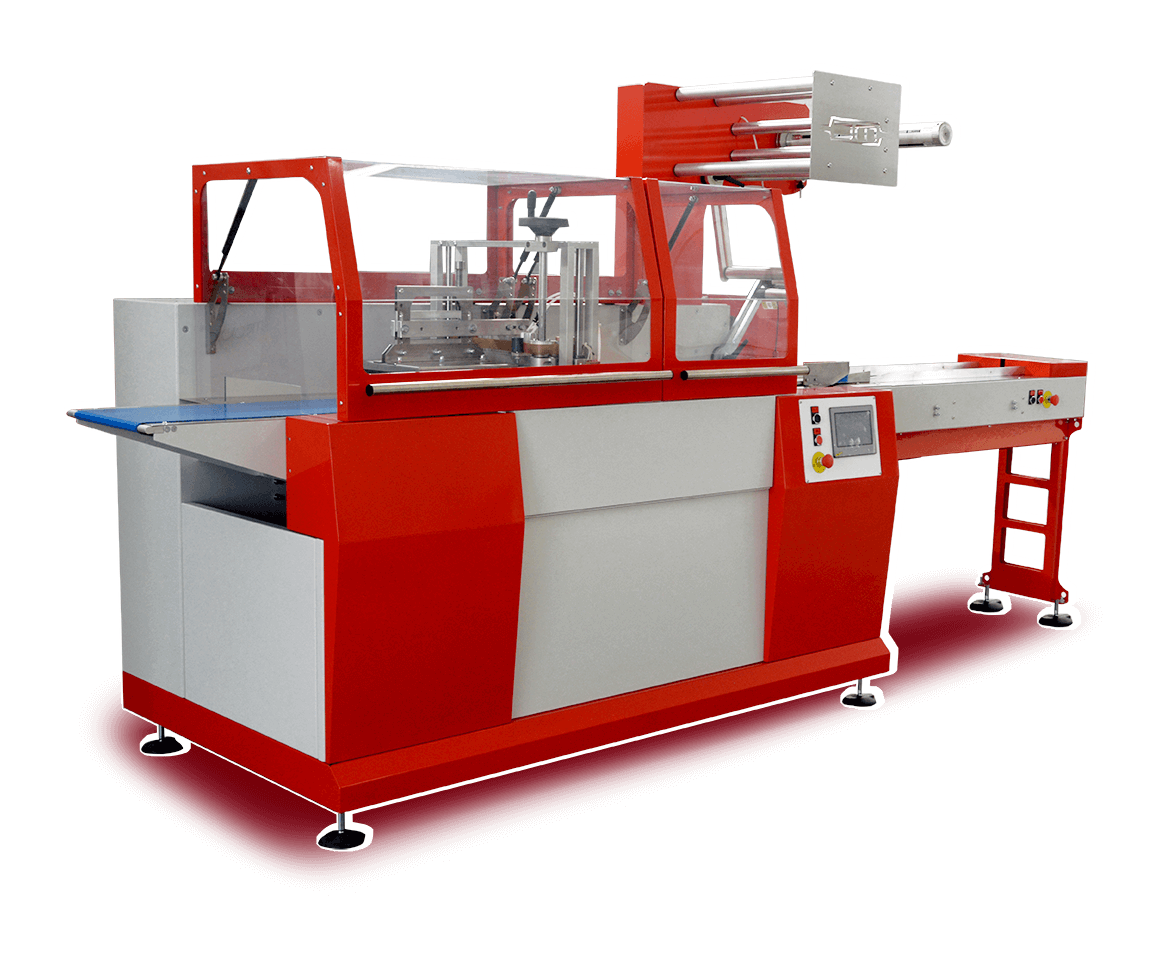

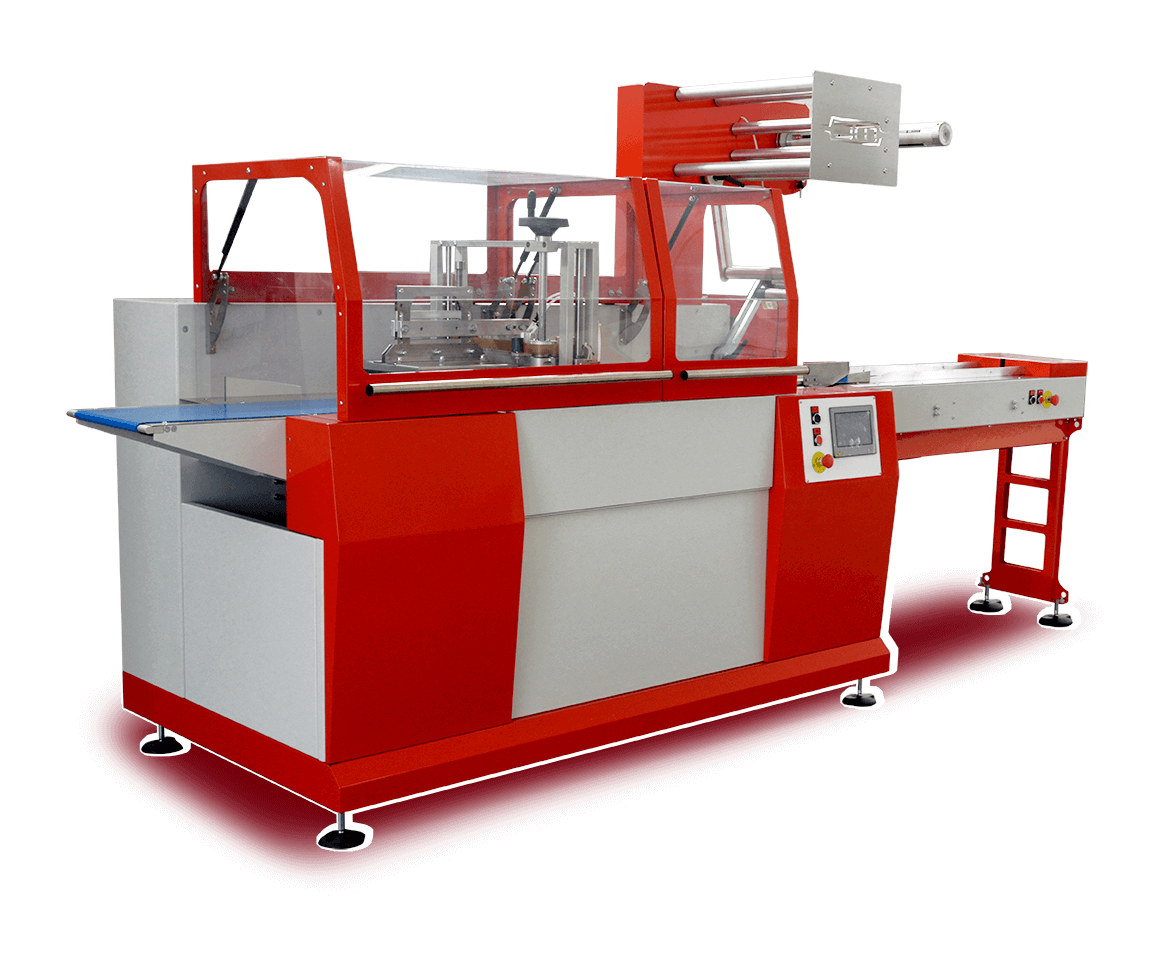

EWP 600 Box Motion

Designed for ATM packaging, versatile and also suitable for thicker and more resistant films.

Ideal for

wrap

pizza

meat

cheeses

sausages and cold cuts

Why

choose it

- Manages welding times

- Perfect for modified atmosphere packaging

- Advanced technology, and easily controlled via the touch-screen interface

Until

50 packs per minute

Maximum film reel size: 600mm