Automatic

The new model of automatic shrink wrap machine is the result of constant attention to market needs, with the aim of proposing a technologically advanced but flexible and extremely compact product.

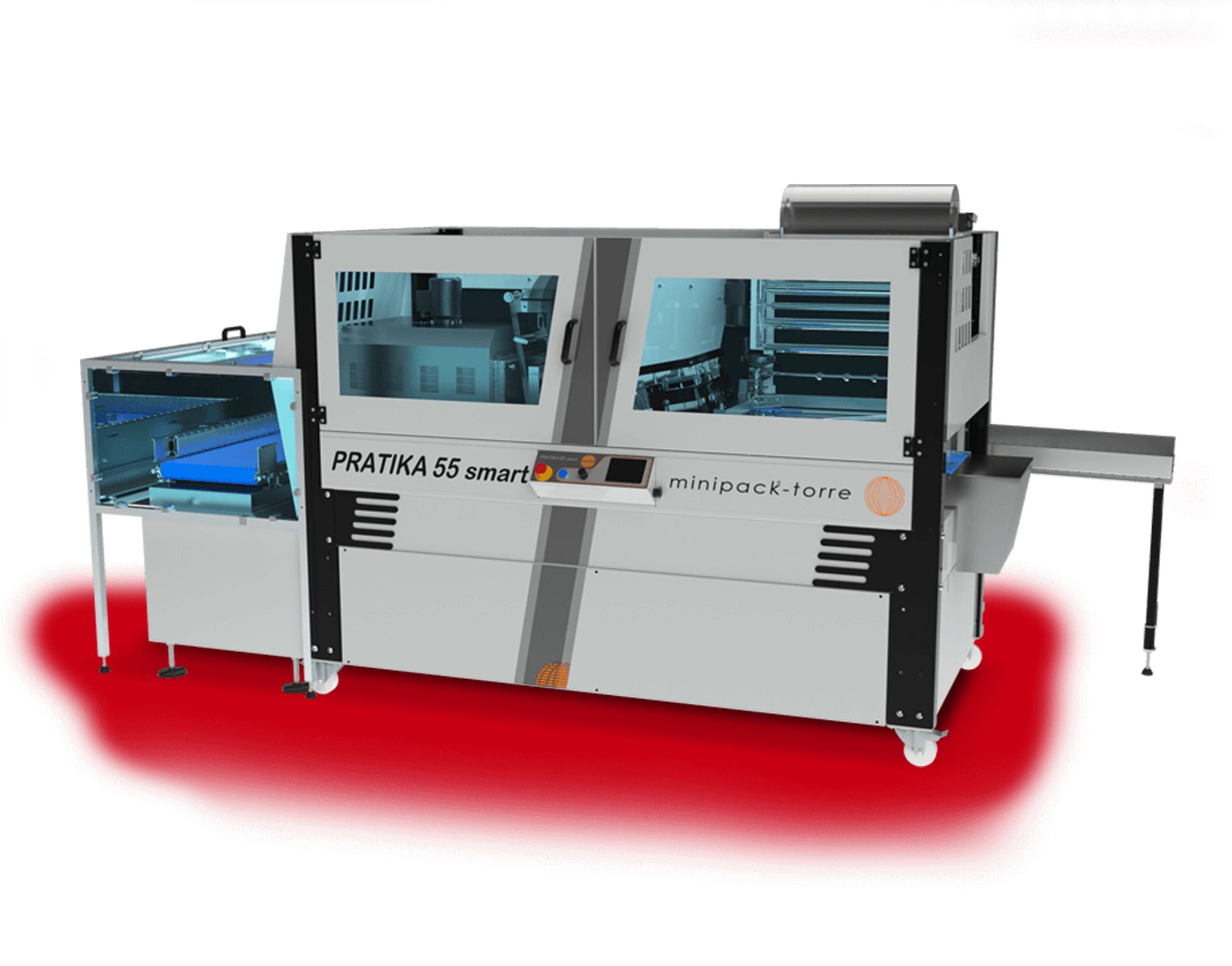

Pratika 55 Smart

The automatic shrink wrap machine with incorporated tunnel

The new model of automatic shrink wrap machine is the result of constant attention to market needs, with the aim of proposing a technologically advanced but flexible and extremely compact product. The included tunnel, revolutionary in the world of automatic machines, meets space needs, but above all reduces labour costs to a minimum, thanks to the single operator patented "come back" option. Enhanced with strong mechanical and electronic technological content, the new Pratika 55 Smart is a perfect synthesis of reliability, versatility and safety, which once again evolves our way of conceiving the compact automatic shrink wrap machine.

Technical characteristics

- L-sealing system

- Schneider Electric PLC M221 con 128 customisable and named programs

- 4.3 inch colour touchscreen control panel

- USB and SD communication interface

- Schneider Electric Brushless motor drive

- Microperforation device with film tensioning adjustment on the set product height

- Height-adjustable triangles and sealing bar

- Sealing bar opening settable from touchscreen control panel

- Belt speed (infeed/outfeed) adjustable by programmable Schneider Electric inverter Altivar model (optional)

- Connectors for interface with supplementary unloading and loading belts

- Standard belts compliant with the strictest regulations in force in the food sector (FDA) and completely antistatic

- Motorised waste winder

- Incorporated tunnel with low energy consumption

Optionals

- “Come back" belt kit

- Outfeed guide kit with vertical rollers

- Inverter for changing belt speed

- Stainless steel loading shelf kit

- Transparent cover for "Come Back" belt kit

- Vertical photocell kit -

- Wireless pushbutton panel kit

- "Easy Open" Smart label applicator

- Applicator support

Pratika 56

Excellence among shrink wrap machines

The PRATIKA 56 is a fully automatic innovative packaging machine, the basic model in a range of products that sets a new standard in the field of automatic shrink wrap machines. High technological, mechanical and electronic content and guaranteed reliability are the common features of a line of machines with specific packaging characteristics, each representing a concrete answer to particular needs. This shrink wrap machine model includes the functionality of the standard belt system.

Technical characteristics

- Power supply 230V

- Phase ph1

- Max installed power 2.5 kW

- Air supply 5 bar

- Hourly production p/h (pph) 0-2400

- Working dimensions of sealing bars 600x400 mm

- Max product dimensions 600x400x160 mm

- Max reel dimensions (diameter) 300 mm

- Max reel dimensions (width) 700 mm

- Height of worktop 870 mm (h. infeed belt)

- Machine dimensions (guards open) 2480x1490x h.1960 mm

- Machine dimensions (guards closed) 2480x1240x h.1675 mm

- Machine weight (Net/Gross) 585/721 kg

Pratika 56 CS

Automatic shrink wrap machine for centre sealing

The PRATIKA 56 CS is a completely innovative automatic packaging machine that sets a new standard compared to other similar machines in the field of automatic shrink wrapping. Technological, mechanical and electronic content of high level together with guaranteed reliability are the shared features of a line of machines with special packaging characteristics: each provides a concrete answer to specific needs. The PRATIKA 56 CS creates a seal right in the middle of the piece (CS stands for CENTRE SEALING) moving the whole structure so that the seal closes horizontally in the middle of the product. This shrink wrap machine includes the functionality of the standard belt approach system.

Technical characteristics

- Power supply 230V

- Phase ph1

- Max installed power 2.5 kW

- Air supply 5 bar

- Hourly production p/h (pph) 0-2400

- Working dimensions of sealing bars 600x400 mm

- Max product dimensions 600x400 h.240 mm

- Max reel dimensions (diameter) 300 mm - -

- Max reel dimensions (width) 700 mm

- Height of worktop 870 mm (h. infeed belt)

- Machine dimensions (guards open) 2480x1490x h.1960 mm

- Machine dimensions (guards closed) 2480x1240x h.1675 mm

- Machine weight (Net/Gross) 670/806 kg

Optionals

- Photocell for printed film

- Photocell reel and film end

- Connectable infeed and outfeed belt

- Pressure switch

- Can be combined with retraction tunnel.

Pratika 56-T MPS

Beyond the limits of automatic continuous shrink packaging machines

The new PRATIKA 56-T MPS is an automatic shrink wrap machine which comes as standard with a Side Seal device, continuous sealing with no length limitations, as well as Centre Sealing and fully electric operation. This machine can package formats up to 400 mm wide x 240 mm high, and has been upgraded in all its mechanical and electronic components to reach an output of up to a maximum of 3600 pieces per hour (depending on the size of the product and the film used). The shrink-wrap machine is built on a new T body that includes an independent electrical system located in the rear part of the machine. The PRATIKA 56-T MPS thus represents a perfect synthesis of reliability, high performance, versatility and safety, further evolving the conception of automatic shrink film packaging machines.

Technical characteristics

- Schneider Electric PLC M258 with 256 customisable and namable programs

- 5.7 inch colour touchscreen control panel, 10 languages

- 2 Dual Core microprocessors (like 4) 2 x 32 bit

- USB communication interface

- Schneider Electric brushless motor drive

- Signalling reel and film-opening roller position on the set product height

- Microperforation device with film tension adjustment to the set product height

- New closed-loop sealing bar actuation frame that balances forces and makes movement smoother

- Self-adjustment of triangle and bar height to set product height

- Sealing bar opening defined by product height, which may be set on the touch-screen control panel

- Belt speed (infeed/outfeed) regulated by programmable Schneider Electric inverter Altivar model

- Electronic port (infeed/outfeed) for interfacing with supplementary unloading and loading belts

- Standard belts compliant with the strictest regulations in force in the food industry (FDA) and fully antistatic

- Full waste winder electronic warning device

- Possibility of adding a retraction tunnel.

Find out about our automatic packaging solutions

Shrink tunnel

The shrink tunnels have been built with significant technical and aesthetic updates, in order to...

Chamber machines

We have never abandoned our pioneering spirit. It was in fact the invention of the first chamber...

Automatic

The new model of automatic shrink wrap machine is the result of constant attention to market needs,...

Taping machines

We have a wide range of fixed or fully robotised pallet wrappers. Extremely fast, sturdy machines...

Check Weigher

This is used to check whether the weight of an individual package conforms to the preset weight or...

X Bag

X-BAG evo is the ideal solution for those who need to pack small quantities of material quickly...

Doy-Pack packaging machines

The Doy Pack packaging machine is the latest generation of horizontal equipment.

Strada del Cascinotto 230 - 10156 - Turin

Turin+39.011.99.10.455

Mon - Fri 8.30 - 18.30info@dmpackagingroup.com

Technical support

Are you looking for more performing industrial automatic systems?

ask for the support of HBTS, the dedicated DM Packaging Group brand